Need proper danger signs to ensure your worksite remains a safe place and accidents are not a daily thing to worry about? Then you need LDC Equipment (SHR) to provide you with excellent quality, fully compliant danger signs. Unlike general safety signage, danger signs are used exclusively to signal immediate, life-threatening risks—and they must be designed, placed, and maintained with that urgency in mind.

Their purpose isn’t to inform passively; it’s to interrupt behaviour and prevent irreversible mistakes. Whether marking a high-voltage switchboard, a confined space, or a toxic gas zone, these signs communicate one simple message: stop and assess before proceeding. At LDC Equipment (SHR), we specialise in danger signage engineered for harsh Australian conditions, built to comply with AS 1319:1994 and meet the real-world needs of high-risk worksites. If your team is exposed to critical hazards, talk to us about durable, compliant danger signage that delivers when it matters most.

If you’re not familiar with danger signs for worksite safety, these are the 3 main aspects to keep in mind:

- Danger Signs Are Treated Differently Under AS 1319

Not all signs carry the same weight. Under AS 1319, danger signs are reserved for hazards that will cause serious injury or death if not avoided. This is why their colour scheme is so distinct: red, black, and white. Completely designed to command immediate attention. Unlike caution or warning signs, which indicate potential risks, danger signs are absolute. Their misuse not only undermines their credibility but can also result in regulatory breaches.

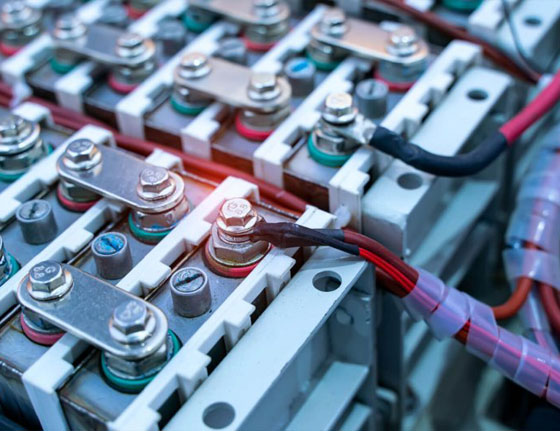

A danger sign saying “High Voltage” doesn’t leave room for interpretation, it’s a clear operational trigger for action. These signs are found near electrical switchboards, confined spaces, pressure systems, gas installations, and other high-risk equipment. For them to be compliant and effective, they must be legible from a reasonable distance, securely mounted, and constructed from materials that won’t degrade in weather, sunlight, or corrosive environments.

- Effective Placement is Non-Negotiable

A danger sign loses its value the moment it’s blocked, faded, or installed in the wrong place. Signage is only effective when it appears exactly where the risk occurs—not 10 metres away, not behind a barrier, and not competing with a dozen unrelated signs. Whether mounted on a trailer, wall, scaffold, pole or vehicle, the sign must trigger immediate recognition and decision-making before someone is exposed to danger.

Placement strategy should account for the site’s layout, typical traffic flow, line-of-sight, and lighting conditions. On night works or in dark environments, signs may need retroreflective or photoluminescent finishes to stay visible. In areas where noise levels prevent verbal communication, signage becomes the primary method of warning.

- Integrating Danger Signs into Your Safety Culture

Installing danger signs isn’t a one-time task: it’s part of a dynamic system that includes training, audits, and signage maintenance. Workers must know how to interpret these signs and take them seriously. If a sign becomes part of the background or is ignored due to overuse, it fails. That’s why site-specific messaging matters.

Regular audits—at least every 6 to 12 months—ensure signs remain intact, visible, and relevant. Any that are faded, outdated, or damaged must be replaced immediately. Signage should also evolve with your site: as operations change, risks shift, and layouts get updated, your signage strategy should follow suit.

When danger signs are positioned and respected as part of a broader safety culture, they become more than just compliance tools; they become part of the way your team thinks and works on-site.

At LDC Equipment (SHR), we manufacture Australian-made, WHS-compliant danger signs designed to stand up to heat, rain, dust, and rough handling. From electrical zones to chemical storage and confined space entry points, our signs are built to be seen, understood, and respected.